Motec Boost control features ?

11 posts

• Page 1 of 2 • 1, 2

Motec Boost control features ?

I'm wanting to know the complete capabilities of Motec boost control.

- MidShipCivic

- Posts: 6

- Joined: Thu Sep 18, 2008 1:32 pm

Re: Motec Boost control features ?

That is fairly an open ended question.

What there is, is that the MoTeC ecu hase a Boost control Feature built in that can be leveraged when you assign one of the Aux output to Function: 1 (Boost Control).

How you do the Boost control at that point is tied to what you will use for boost controlling (ie Just MAP, or Map vs Ground Speed etc).

So that is the best I can do with the little bit of information you gave.

What there is, is that the MoTeC ecu hase a Boost control Feature built in that can be leveraged when you assign one of the Aux output to Function: 1 (Boost Control).

How you do the Boost control at that point is tied to what you will use for boost controlling (ie Just MAP, or Map vs Ground Speed etc).

So that is the best I can do with the little bit of information you gave.

- figgie

- Posts: 135

- Joined: Fri Jul 11, 2008 4:22 am

- Location: Minnesota, USA

Re: Motec Boost control features ?

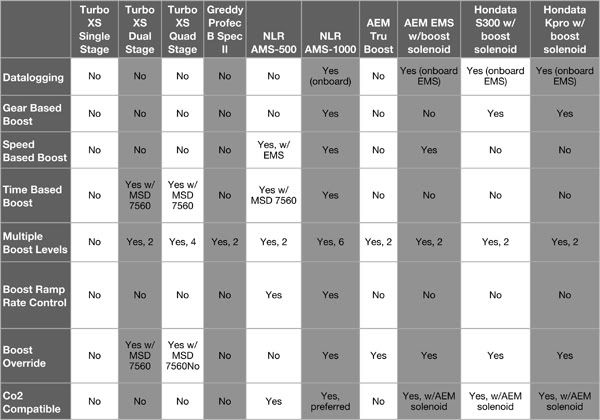

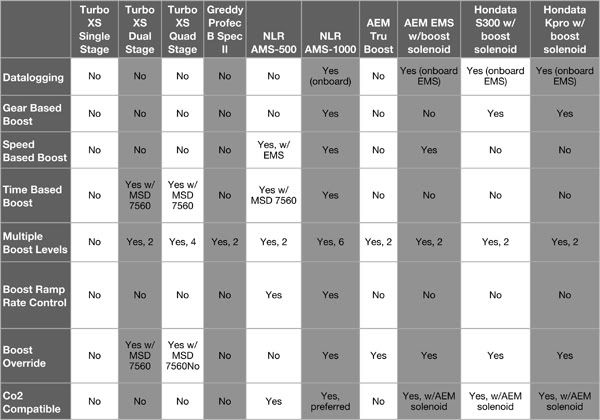

If you were to put it in this list:

How does it compare to say the AMS unit is it as versatile?

How does it compare to say the AMS unit is it as versatile?

- MidShipCivic

- Posts: 6

- Joined: Thu Sep 18, 2008 1:32 pm

Re: Motec Boost control features ?

if it were in that list it would be

yes - onboard

yes

yes

yes

yes - as many as you can think of

yes

yes

yes

Your not going to find a boost controller with better capabilities. I am sure that you will never use the full ability of motec's boost control (no offense, i doubt anyone else here does it would really just be over complicating things).

yes - onboard

yes

yes

yes

yes - as many as you can think of

yes

yes

yes

Your not going to find a boost controller with better capabilities. I am sure that you will never use the full ability of motec's boost control (no offense, i doubt anyone else here does it would really just be over complicating things).

- Ben-S

- Posts: 134

- Joined: Fri Jul 11, 2008 12:39 am

Re: Motec Boost control features ?

Ben-S wrote:if it were in that list it would be

yes - onboard

yes

yes

yes

yes - as many as you can think of

yes

yes

yes

Your not going to find a boost controller with better capabilities. I am sure that you will never use the full ability of motec's boost control (no offense, i doubt anyone else here does it would really just be over complicating things).

Thanks Ben you've answered my question fully this is what I was looking for.

- MidShipCivic

- Posts: 6

- Joined: Thu Sep 18, 2008 1:32 pm

Re: Motec Boost control features ?

Maybe a better question would be....

What do you need a boost controller to do ?

What do you need a boost controller to do ?

- stevieturbo

- Posts: 503

- Joined: Fri Jul 11, 2008 3:32 am

Re: Motec Boost control features ?

motec does not have a shift counter which i have asked for for drag racing.

- busaman

- Posts: 20

- Joined: Tue Jul 15, 2008 4:35 am

Re: Motec Boost control features ?

busaman wrote:motec does not have a shift counter which i have asked for for drag racing.

a shift counter? It has gear detection based on numerous parameters. Like gear based on ground speed or gear based on strain gauge. So what is different between a counter and the MoTeC knowing what gear you are in?

Are you asking because of Gear based boost compensation? If so I know the MoTeC CAN do that.

- figgie

- Posts: 135

- Joined: Fri Jul 11, 2008 4:22 am

- Location: Minnesota, USA

Re: Motec Boost control features ?

There a number of comp tables available (up to around 5 or 6 from memory)....some of these are 3D (two input axes), some are 2d (one axis only). My only complaint is i'd like a few more tables! I currently have a very carefully mapped boost control system, closed loop (ie: not a table of duty cycles), with inputs from RPM, TP, Gear, Vehicle speed, turbine RPM, Comp inlet pressure and rate of change of engine rpm. The boost table (requested boost) is a function of ALL I run a turbo race car, with runs an inlet restrictor, adding several extra dimensions to the boost lag/ boost control problem. I have essentially tried to emulate a "torque based" function, whereby the boost map is essentially a map of available torque, and the pedal input becomes essentially the input for "requested percentage of available torque".

The Motec M800 that i'm using is the ONLY readily available ECU that had the flexibility & number of inputs & tables to remotely approach what i was doing (short of using an OEM based controller, which i wanted to avoid for many reasons, even though i have the ability to reprogram it live and access to all functions).

You see, your question should not be "what does it do?" because that is only limited by your ingenuity and imagination and ability to adapt it your your specific application (and to some extent the total number of tables available). Of all the options i looked at for boost control, the M800 was the MOST FLEXIBLE and most sophisicated...that does not always mean it is the best, though, because the more sophisticated, generally the more difficult & time consuming it is to set up.

But, for really good boost control on an M800 (and ANY ECU), my tips would be:

1. PI closed loop control (duty cycle table open loop control is simple to get going, but any change to acuator positon, turbo, inlet, can dramatically affect your boost values.) . For accurate control you MUST accurately populate the "actuator average postion" duty cycle table, as this provides the feed-forward entry point for the PI control to RAPIDLY get to the boost setpoint. (mine's within 1.5kPa at ANY speed & load).

2. Boost request should be against TP & RPM as a minimum in my opinion, for the best overall response (from experience in OEM turbo development work & aftermarket "tuned" cars)...you will get similar "big numbers" controlling boost other ways, but never the OE level driveability & linear response that makes it so much easier to drive faster!

3. You need to ensure your wastegate actuator has min-boost set approx 80% of your minimum desired boost (but high enough to prevent creep from high pre-turbine manifold pressure at high rpm).

4. Appropriate sized solenoid valve to ensure good range of duty cycles.

It sounds like your application is for drag racing, so things like gear detection (you need either wheel or talishaft speed, and the motec will determine what gear your in...works VERY well) to provide different boost limits, but also i would think you would apply a modifier for rate of chage of engine rpm (to detect wheelspin, and trim boost), fully closed wastegate on gearshift (and spk retard / cut to build some boost between gears ala FG XR6T!!), and even solenoid operated BOV open on shift...in fact i thnk given you are probably also in a traction limited environment, you essentially want to emulate a torque-based environment.....but i think transitional driveability is not such a concern for the qtr mile!

I personally think you can't go wrong or find a better BOOST CONTROL system....if you, or someone you know, has the skils to set it up, and is prepared to put the time in. Even in simple mode, it is very effective, purely based on the flexibility of the tables, and what you can make it a function of......you can have a pot on one input to dial in a modifier, or switched boost, the sky's the limit. Compared to the others in the table you provided, in my experience, the M800 has no peer. The EFI tech Euro ECU's come close with boost control (OEM quality), but they are fiddly to cal, and not as readily configurable & customisable as the M400-600-800.

The others in the list are essentially an "add-on" boost controller....the M400-800 is an integrated, holistic engine controller....no comparison!

You would not be disappointed!

The Motec M800 that i'm using is the ONLY readily available ECU that had the flexibility & number of inputs & tables to remotely approach what i was doing (short of using an OEM based controller, which i wanted to avoid for many reasons, even though i have the ability to reprogram it live and access to all functions).

You see, your question should not be "what does it do?" because that is only limited by your ingenuity and imagination and ability to adapt it your your specific application (and to some extent the total number of tables available). Of all the options i looked at for boost control, the M800 was the MOST FLEXIBLE and most sophisicated...that does not always mean it is the best, though, because the more sophisticated, generally the more difficult & time consuming it is to set up.

But, for really good boost control on an M800 (and ANY ECU), my tips would be:

1. PI closed loop control (duty cycle table open loop control is simple to get going, but any change to acuator positon, turbo, inlet, can dramatically affect your boost values.) . For accurate control you MUST accurately populate the "actuator average postion" duty cycle table, as this provides the feed-forward entry point for the PI control to RAPIDLY get to the boost setpoint. (mine's within 1.5kPa at ANY speed & load).

2. Boost request should be against TP & RPM as a minimum in my opinion, for the best overall response (from experience in OEM turbo development work & aftermarket "tuned" cars)...you will get similar "big numbers" controlling boost other ways, but never the OE level driveability & linear response that makes it so much easier to drive faster!

3. You need to ensure your wastegate actuator has min-boost set approx 80% of your minimum desired boost (but high enough to prevent creep from high pre-turbine manifold pressure at high rpm).

4. Appropriate sized solenoid valve to ensure good range of duty cycles.

It sounds like your application is for drag racing, so things like gear detection (you need either wheel or talishaft speed, and the motec will determine what gear your in...works VERY well) to provide different boost limits, but also i would think you would apply a modifier for rate of chage of engine rpm (to detect wheelspin, and trim boost), fully closed wastegate on gearshift (and spk retard / cut to build some boost between gears ala FG XR6T!!), and even solenoid operated BOV open on shift...in fact i thnk given you are probably also in a traction limited environment, you essentially want to emulate a torque-based environment.....but i think transitional driveability is not such a concern for the qtr mile!

I personally think you can't go wrong or find a better BOOST CONTROL system....if you, or someone you know, has the skils to set it up, and is prepared to put the time in. Even in simple mode, it is very effective, purely based on the flexibility of the tables, and what you can make it a function of......you can have a pot on one input to dial in a modifier, or switched boost, the sky's the limit. Compared to the others in the table you provided, in my experience, the M800 has no peer. The EFI tech Euro ECU's come close with boost control (OEM quality), but they are fiddly to cal, and not as readily configurable & customisable as the M400-600-800.

The others in the list are essentially an "add-on" boost controller....the M400-800 is an integrated, holistic engine controller....no comparison!

You would not be disappointed!

- SportsCarRacer

- Posts: 34

- Joined: Tue Jul 15, 2008 11:21 pm

11 posts

• Page 1 of 2 • 1, 2

Return to M400, M600, M800 and M880 ECUs

Who is online

Users browsing this forum: No registered users and 5 guests