Page 1 of 2

Engine Synchro Pin and Speed Pin Debounce

Posted:

Mon Feb 07, 2022 3:14 pmby glausb23

Hello,

Should the Engine Speed Pin Debounce and Engine Synchronisation Pin Debounce settings match for each RPM value in the engine's speed range?

I have a 2014 Yamaha YZF-R6 engine which I am currently having difficulty getting to startup on the engine dyno. Looking back through my initial setup parameters, I noticed that the debounce settings for these two parameters are very different, and am wondering if this is causing excessive filtering and thus contributing to the no-start condition I'm currently having with this engine.

I currently have Engine Synchronisation Pin Debounce set to 4 micro-seconds for all engine speeds, while Engine Speed Pin Debounce is set at the following values: 120 micro-seconds @ 0 RPM, 100 micro-seconds @ 500rpm, 80 micro-seconds @1000 rpm, 5 micro-seconds @2000 rpm, and again 5 micro-seconds @ 20,000 rpm.

Do these values sound about right for this engine/application, or are modifications likely needed?

Any help is greatly appreciated!

Benjamin

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Mon Feb 07, 2022 3:31 pmby Stephen Dean

Hi Benjamin,

Is the Synchronisation Pin a Hall Effect sensor and the Engine Reference Sensor a Magnetic sensor? If so, then these numbers for the Synchronisation pin are correct as the Hall signal is a filtered signal so doesn't need as large a window.

With the Reference Signal, what is the tooth count that you have for the crank trigger? My typical starting numbers for a Reference Signal is as follows.

- Engine Speed Pin Debounce.PNG (3.93 KiB) Viewed 9129 times

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Tue Feb 08, 2022 4:43 amby glausb23

Hello,

Thank you for the quick response and clarification on these settings.

The crank trigger is a two-teeth missing wheel which would have 24 teeth if no teeth were missing, but has 22 due to the 2 missing teeth.

Benjamin

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Tue Feb 08, 2022 9:09 amby NathanB

Hi,

Quite often with bikes, the high cop, low interia and small batteries cause a bit of an issue.

We have two settings called the narrow and wide tooth threshold. These are validations for the change in pitch allowed from one tooth to the next.

Due to inconsistent cranking often with bikes, this can play havoc, especially when battery voltage drops. Keeping a wide narrow and wide tooth threshold (45% narrow and 190% for wide), ensure you have a little bit of throttle opening, and ensure you have a good battery.

I have attached a picture of an input capture of an R1 superbike cranking on low battery voltage, you can see with how the pitch changes dramatically as you get to the compression of each cylinder, so much that the missing tooth is not very different to the normal teeth.

A typical symptom of this is if the bike gives a few kicks (without starting) you will drop out of cycle lock on each kick, due to the aggressive pitch change)

The engine speed diagnostic will give you a good indication what is going on if you are not achieving and holding cycle lock on cranking. If you are achieving and holding cycle lock, your issue may be elsewhere.

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Tue Feb 08, 2022 10:16 amby Stephen Dean

Also,

The missing teeth are counted in the Engine Speed Reference Tooth Count parameter, If this is set to be less than the actual number then the M1 will miscalculate the engine position.

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Tue Feb 08, 2022 4:18 pmby David Ferguson

Make sure the channel Engine Run Switch is ON. Without this the ignition and injector outputs are disabled, and the engine won't start.

I just went through this where the Engine Run Switch index was a Driver Switch that I changed. I didn't realize it was using that, and so I didn't realize it was now OFF. Could not figure out why the engine suddenly wasn't firing....

I noticed this when using M1 Tune ->Diagnostics->Fuel Outputs tab. Fuel State was "Disabled". The Ignition Outputs tab has similar view of the Ignition State.

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Tue Feb 08, 2022 5:43 pmby glausb23

Hello,

Thank you both for the informative responses. Reflecting on some of the above parameters that you've mentioned:

I have the Engine Speed Reference Tooth Count parameter set to 24, which accounts for the full number of evenly spaced teeth that would be on the wheel. Therefore, that shouldn't be an issue.

I also have not noticed the engine kicking in and out of cycle lock during cranking, though I will say I haven't necessarily watched that status closely while the engine is cranking--I will look into that tomorrow. I currently have the Narrow Pitch Threshold set to 50% and the Wide Pitch Threshold set to 150%. The engine does start and run for short periods of time with the above-mentioned settings.

In fact, after making some changes to the idle actuator settings and the debounce changes that were suggested previously, I can now get the engine to run for up to about a minute.. though it runs poorly during that time.

The battery is connected to a 12V maintainer during and between cranking sessions, so voltage should be staying at a reasonably high level.

The Idle Actuator Throttle Aim Maximum parameter is currently set to 6.0% and seems to be right around where we get the best results thus far after experimenting with different values for this parameter.

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Tue Feb 08, 2022 5:51 pmby glausb23

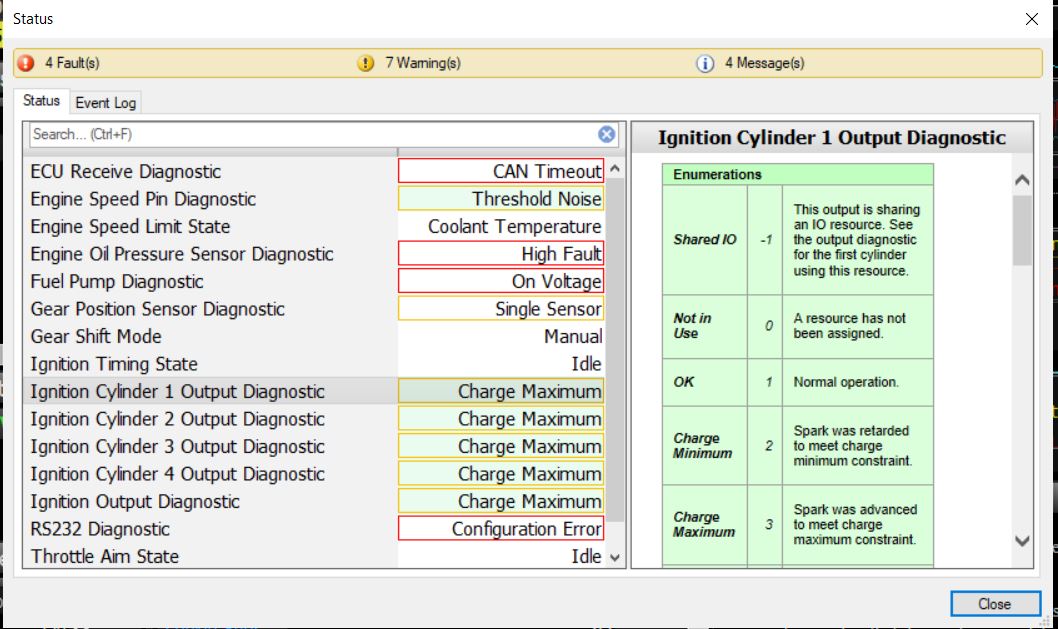

I would like to add, I am getting "Charge Maximum" status for the Ignition Output Diagnostics on all four cylinders of the engine when looking at the "show status" window with the engine idling. I've attached a snippet that I was able to capture of this while it was occuring. Any idea what issue may be causing this status, rather than the "OK" status that I'm assuming I should be seeing for normal operation?

- Charge Maximum Snippet.JPG (126.69 KiB) Viewed 9097 times

If desired, I've also attached the M130's current package for you to look through and see if you notice any settings drastically in error of what they should be.

Any further help on this would be greatly appreciated!

Benjamin

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Wed Feb 09, 2022 9:03 amby Stephen Dean

Hi,

Where did you get the dwell times for the coils?

The Charge Maximum diagnostic can occur if there is a very short dwell time (as is the case with these coils) and the Ignition Coil Charge Limit Maximum has a low limit. If the Ignition Timing changes leading to the M1 having to dwell the coils for longer than has been allowed in the configuration, The M1 will discharge the coils early to protect the coils from being over dwelled.

Re: Engine Synchro Pin and Speed Pin Debounce

Posted:

Wed Feb 09, 2022 12:59 pmby glausb23

Hello,

I set the coil dwell times based on the numbers given to me in another forum post on here. I received an excel spreadsheet from MoTeC directly based on coil characterization results for the Mitsubishi F6T568 coils.

Since these dwell times (based on varying battery voltage levels) are presumably accurate because they came directly from MoTeC, would you suggest increasing the Ignition Coil Charge Limit Maximum value to correct this condition?

Thanks,

Benjamin