Chasing a flat spot

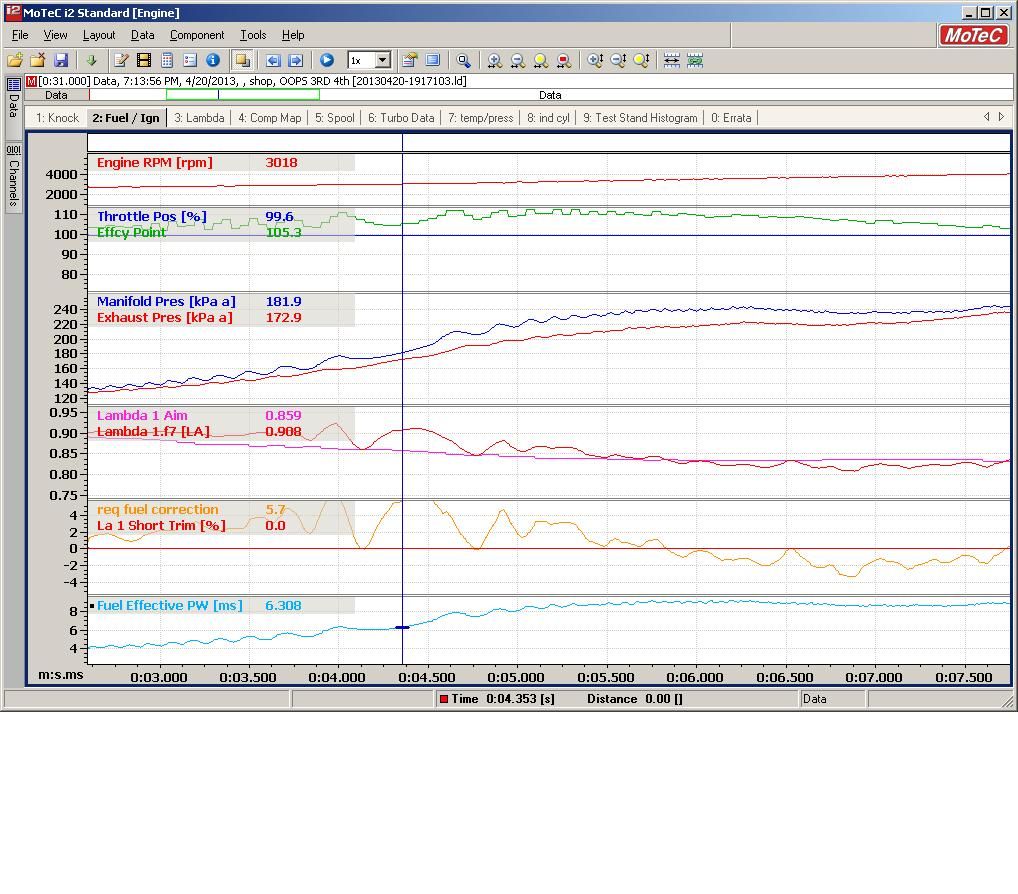

My turbo Honda Insight (running M400) has a little flat spot at 3800 rpm, full throttle. Second gear is when it is most noticeable.

I noticed boost dropped a little at this spot so put in a special site to address this via a slightly higher boost control duty cycle. Boost no longer falls, but flat spot still there. Nothing obviously different in timing or fuel at that spot.

I tried some variations in fuel and timing at just that site and by leaning it out a lot I was able to improve it (just the one site!) but then I noticed that in different gears (eg third) the car was going too lean as it went past that spot - I imagine because it is there longer. I then returned mixtures and timing numbers back to how they were previously.

I can only guess that there's some sort of odd intake resonance at that combination of revs and boost (and rate of change of engine speed?) - but that doesn't help me fix it!

It's noticeable enough that the car feels poorly tuned - anyone got any ideas?

I noticed boost dropped a little at this spot so put in a special site to address this via a slightly higher boost control duty cycle. Boost no longer falls, but flat spot still there. Nothing obviously different in timing or fuel at that spot.

I tried some variations in fuel and timing at just that site and by leaning it out a lot I was able to improve it (just the one site!) but then I noticed that in different gears (eg third) the car was going too lean as it went past that spot - I imagine because it is there longer. I then returned mixtures and timing numbers back to how they were previously.

I can only guess that there's some sort of odd intake resonance at that combination of revs and boost (and rate of change of engine speed?) - but that doesn't help me fix it!

It's noticeable enough that the car feels poorly tuned - anyone got any ideas?